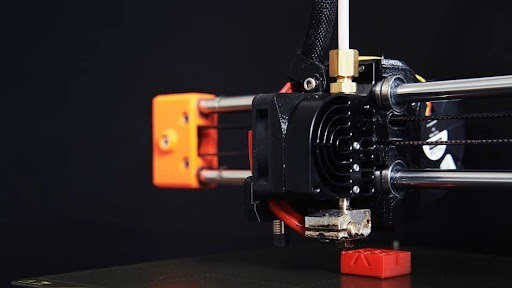

3D printing, sometimes referred to as additive manufacturing, is transforming production in a variety of industries by making it possible to create intricate and personalized parts layer by layer. The fundamental components of this technology are the materials, each of which is selected for a particular use based on its characteristics and suitability for a range of 3D printing methods. This article examines the diverse range of materials used in additive manufacturing, What Are Additive Manufacturing Materials and their special qualities, and their applications across several industries.

Additive Manufacturing Materials: What Are They?

Specially created compounds known as additive manufacturing materials are used as the basic material in 3D printing procedures. These materials fall into a number of categories, such as composites, metals, ceramics, and polymers. Because each category offers unique mechanical, thermal, and chemical qualities, producers can choose the best material for a project according on its particular requirements.

Types of Materials Used in Additive Manufacturing

From sophisticated, high-performance items to rapid prototyping, the universe of additive manufacturing materials is broad. A closer look at the primary types is provided below:

1. Plastics and other polymers

Because of their many mechanical qualities, affordability, and adaptability, polymers are among the most widely utilized materials in additive manufacturing.

- Thermoplastics: Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), and Polyethylene Terephthalate Glycol (PETG) are materials often utilized in consumer goods and prototyping.

- Photopolymers: Photopolymers are perfect for high-detail prototypes because they harden when exposed to light, which is why they are employed in procedures like SLA (Stereolithography).

- Nylon: Used in industries needing long-lasting materials, including as automotive and aerospace components, nylon is renowned for its strength and flexibility.

Applications include toys, consumer items, medical equipment, automobile components, and prototype models.

2. Metals

Metal 3D printing has made it possible for sectors like healthcare, automotive, and aerospace to produce strong, high-performing components that can survive harsh environments.

- Stainless Steel: Stainless steel is widely used in industries that need high-strength parts because of its strength and resistance to corrosion.

- Titanium: Used in aircraft and medical implants, titanium is biocompatible, strong, and lightweight.

- Aluminum: Known for its strength and light weight, aluminum is perfect for use in aerospace and automotive applications.

- Nickel Alloys: Used in the energy and aerospace industries for components like turbine blades, nickel alloys have a high heat resistance.

Applications include industrial machinery, medical implants, automotive, aerospace, and energy.

3. Ceramics

Despite being relatively new to additive manufacturing, ceramic materials are becoming more popular because of their chemical stability and heat resistance.

- Alumina (Aluminum Oxide): Because of its hardness and ability to withstand high temperatures, alumina (aluminum oxide) is frequently used in industrial settings.

- Silicon Carbide: Silicon carbide is well-known for its remarkable thermal conductivity and toughness, making it appropriate for high-temperature settings.

- Zirconia: Because of its endurance and biocompatibility, it is frequently employed in the dentistry and medical areas.

Applications include electronics, high-temperature equipment, dental implants, and medical devices.

4. Composites

Composite materials improve their mechanical qualities by combining several materials. They are employed in additive manufacturing to produce things that are stronger, more flexible, and more long-lasting.

- Carbon Fiber Reinforced Polymers: Perfect for sports, automobile, and aerospace equipment, these materials are incredibly strong and lightweight.

- Glass Fiber Reinforced Polymers: Without the extra expense of carbon fiber, glass fiber reinforced polymers provide more strength and durability.

- Kevlar-Reinforced Polymers: Kevlar-reinforced polymers are employed in protective gear and automobile components because of their reputation for being impact resistant.

Applications include protective gear, sporting items, automobiles, aircraft, and structural elements.

5. Biomaterials

Because they may safely interact with biological systems, biomaterials are intended for use in medical applications.

- Hydrogel: Hydrogels are crucial for producing tissue-like structures in bioprinting because they promote cell development.

- PLA and PCL: PLA and PCL are biodegradable, human-body compatible polymers that are frequently utilized in tissue engineering and medical implants.

- Collagen: A naturally occurring protein, collagen aids in tissue development and cell proliferation in tissue engineering.

Applications include regenerative medicine, medication delivery systems, tissue engineering, and medical implants.

Benefits of Materials for Additive Manufacturing

Several significant benefits come from the variety of materials used in additive manufacturing:

Flexibility in Design: with additive manufacturing enables designers to try out intricate geometries and unique ideas that would be difficult or impossible to achieve with conventional production techniques.

Material Efficiency: Compared to subtractive manufacturing methods, additive procedures usually only employ the material required, which reduces waste.

Decreased Lead Times: On-demand manufacturing and rapid prototyping reduce lead times, which speeds up and improves process flexibility in response to design modifications.

Customization: For creating one-of-a-kind, specially designed items that meet specific requirements, additive manufacturing is perfect.

In conclusion

Customized, effective, and high-performance parts for a variety of sectors are now possible thanks to additive manufacturing materials. The variety of materials and their uses will only grow as technology develops, making additive manufacturing a vital instrument in today's production environment. I hope you have got all about What Are Additive Manufacturing Materials.