The process of centrifugation is applied in a variety of fields ranging from dairy processing to scientific research.

Benjamin Robins can rightfully be called the father of the centrifuge. The mechanization behind the device was first invented by Robins in an attempt to figure out drag. This was in the 18th century. Fast the forward to the early 1860s and a fellow by the name Antonin Prandtl modified Robin’s invention and repurposed it for the separation of cream and milk. Prandtl’s brother further modified the mechanization behind the centrifuge and applied it for the extraction of butterfat. This was in 1875. Over the years, the centrifuge has been modified and repurposed for a number of uses. We now have advanced centrifuge systems and round-bottom centrifuge tubes.

Centrifugation Defined

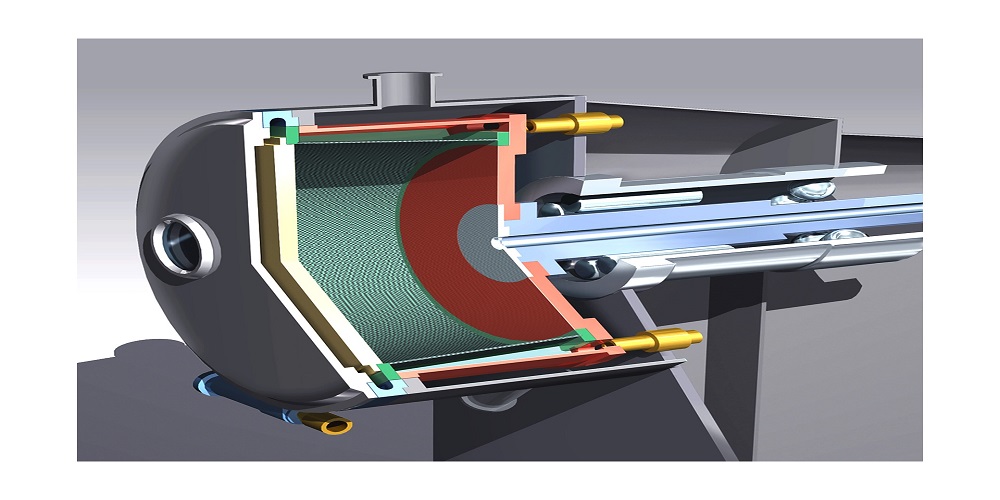

Before we can even explain what centrifugation means, let us start from the beginning and define what a centrifuge is. A centrifuge is basically any machine with a container of

round-bottom centrifuge tubes that rotates at a high speed with the aim of separating materials either by density or use. The mechanization of a centrifuge that has been refined over the years is a rotating arm that was the brainchild of Robins.

Centrifugation is, therefore, a term derived from the separation of materials either by use or density through the use of a centrifuge.

How Does It Work?

A centrifuge relies on a

force known as a centrifugal force for it to be functional. As materials are spun, there exists a force that causes an outward pull on it. Another force that makes a centrifuge effective is the centripetal force. This works in the reverse of a centrifugal force, it pulls inwards as a material is spun.

An illustration of how the two forces work would be that of two materials of different densities being spun at a high speed in the same container. The centrifugal force will cause both materials to be attracted to the container. The centripetal force, however, will cause the less dense material to be towards the center of the container while the denser particles are pulled towards the bottom. The velocity with which these items are drawn to the center will be determined by their closeness to the spinning axis. The further the material from the axis the greater the effect.

Applications of Centrifuges

Centrifuges are in principle all the same. However, differences appear when you consider the speed at which they rotate and the design of the unit responsible for the rotation. These differences are also primary determinants of how the centrifuges are used.

When looking at the design of the unit responsible for rotation, you will find those that maintain fixed angles or those with rotating units constantly shift angles. The latter’s ability to shift angles is attributable to the presence of hinges that give the containers holding the samples the ability to shift outwards as the centrifuge spins faster. Lastly, we have centrifuges that only come with one sample chamber. These are known as a continuous tubular centrifuge.

Centrifuges that are capable of spinning at extremely high speeds are used for molecular or atomic separations. Here, molecules that differ in mass or atomic isotopes that have a difference in mass can be separated. Researchers in the use of nuclear energy or nuclear weaponry make use of centrifuges for isotopic separation purposes.

Centrifuges used in laboratories may differ in shape and size but are generally fixed-angle centrifuges. These make use of a shorter distance between the sample and the line of rotation (axis). They are useful when separating liquids that do not mix, suspensions, blood compositions, DNA and the purification of chemical samples.

Medium-sized centrifuges come in handy when looking to separate solids from liquids. A classic example of such centrifuges is a washing machine. It applies centrifugation to draw water from clothes in the spin cycle.

We have centrifuges that are equal in size to a room. These are used in experiments where high-gravity simulations are required. These are also applicable to the training of pilots. A more enjoyable application of large centrifuges is as rides in amusement parks. The large centrifuges that are not meant for human use have the ability to simulate gravity close to twenty times the usual pull.

Lastly, we have centrifuges for industrial purposes. These are used in the dairy industry to derive various products such as butter and cream from milk, in various chemical industries, to dry materials, as a means of separating drilling fluids and any solid contaminants, for casting metals, and in water treatment plants. The mode of separation will differ depending on the centrifuge and use. For some, it is easier to sediment heavier particles while for others it is easier to use filters.

The process of centrifugation is applicable to more aspects of everyday life than can be imagined. Whether looking to use round-bottom centrifuge tubes or any other type of centrifuge, be sure to understand the relation between the type of the centrifuge and its uses.