Valves are essential components in various industries, controlling the flow of fluids, gases, and steam in pipelines and process systems. With numerous valve types available, it's crucial to understand their characteristics and applications to select the right valve for your specific needs. In this comprehensive guide, we will explore different valve types commonly used in industrial applications and their respective applications. Whether you're in oil and gas, water treatment, chemical production, or any other industry, this guide will help you navigate the world of valves.

Butterfly Valves

Butterfly valves are versatile and widely used due to their compact design, low cost, and ease of operation. They consist of a disc that rotates on an axis to regulate flow. Butterfly valves are suitable for a range of applications, including water treatment, HVAC systems, and even large-scale industrial processes. Their quarter-turn operation and quick shut-off capabilities make them an attractive option for various industries.

Ball Valves

Ball valves, as the name suggests, utilize a ball-shaped disc with a hole in the center to control flow. They offer excellent shut-off capabilities and low resistance to flow, making them ideal for applications that require tight shut-off and high flow rate. Ball valves are commonly found in industries such as oil and gas, chemical processing, and power generation. They are available in both manual and automated configurations.

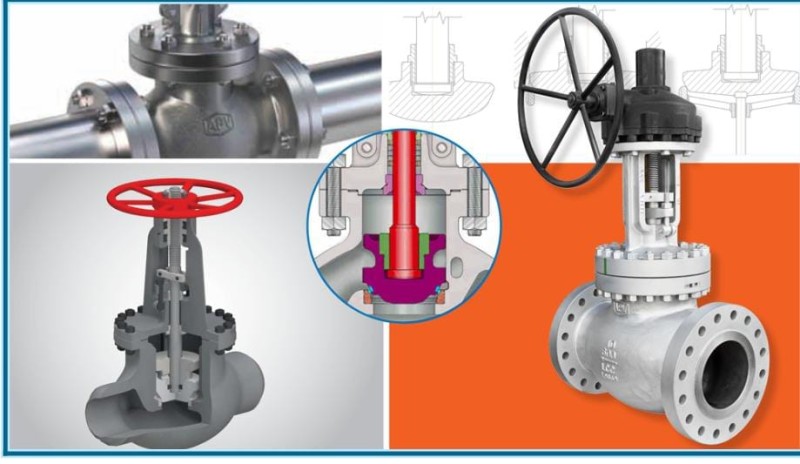

Gate Valves

Gate valves are widely used in industries where a full flow path is required and flow control is not a primary concern. These valves involve a wedge-shaped gate that raises or lowers to either block or permit flow. Gate valves are commonly used in industries such as oil and gas, water treatment, and petrochemicals. They are designed for on-off service rather than throttling, as their flow characteristics are generally not linear.

Globe Valves

Globe valves are named after their spherical shape, with a disc that moves perpendicular to the flow path to regulate flow. They provide excellent control over fluid flow, making them suitable for throttling applications. Globe valves are commonly used in industries such as oil and gas, pharmaceuticals, and food and beverage. With their intricate design, they offer precise flow control and can handle high-pressure applications.

Check Valves

Check valves, or non-return valves, are essential in preventing backflow in pipelines. They allow fluid to flow in one direction and automatically close to prevent reverse flow. Check valves come in various types, including lift check valves and swing check valves. Lift check valves use a disc or piston that moves vertically to allow or block flow, while swing check valves employ a hinged disc that swings on a hinge pin. Check valves are commonly used in water supply systems, wastewater treatment, and oil and gas pipelines.

In conclusion, understanding the different valve types and their applications is crucial for selecting the right valve for your industry. Butterfly valves, ball valves, gate valves, globe valves, and check valves are just a few of the many options available. By consulting reputable butterfly valves manufacturers or valve experts, you can further explore the benefits and limitations of each valve type and make informed decisions for your specific applications. Consider factors such as flow requirements, pressure, temperature, media compatibility, and control needs when selecting valves. With the right valves in place, you can ensure efficient and safe operations in your industrial processes.